We are wishing everyone a Happy New Year! The team here at RAMA WORKS is excited to start fresh and work away at new projects.

The Chinese New Year will fall on Tuesday, February 1st, 2022, starting the Year of the Tiger. Celebrations traditionally last for 3-4 weeks and will result in a halt in manufacturing during the holiday; however, we have many products arriving before this, which our Melbourne warehouse will continue to operate for fulfilment.

Here are the updates for our current projects:

U80-A SEQ2

STATUS: FULFILMENT IN PROGRESS

We have been working around the clock to ensure that you all receive your U80-A SEQ 2 after the long wait. We know this project has taken some time, and we thank you all for patiently waiting and being understanding of the current circumstances. We hope you enjoy your U80-A and make sure to take a snap of your build and tag @ramaworks so we can see your creation!

Please make sure your shipping address is up to date! You can check by logging in at https://ramaworks.store/account/login and navigating to your order.

Note: Changing your default address will not update past orders.

If you need to correct your shipping address, please get in touch with us at support@rama.works or https://support.rama.care/

Remember to include your order number!

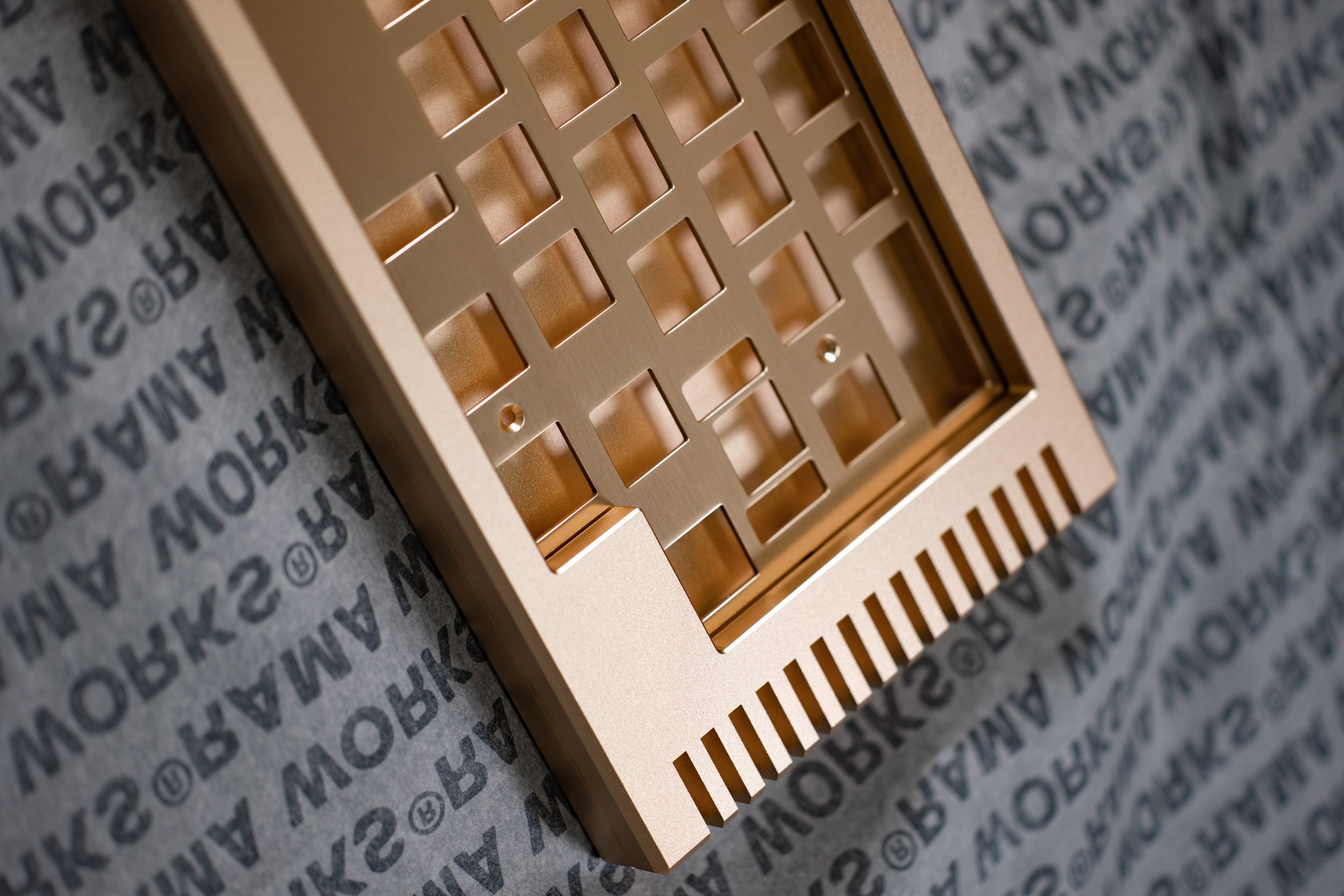

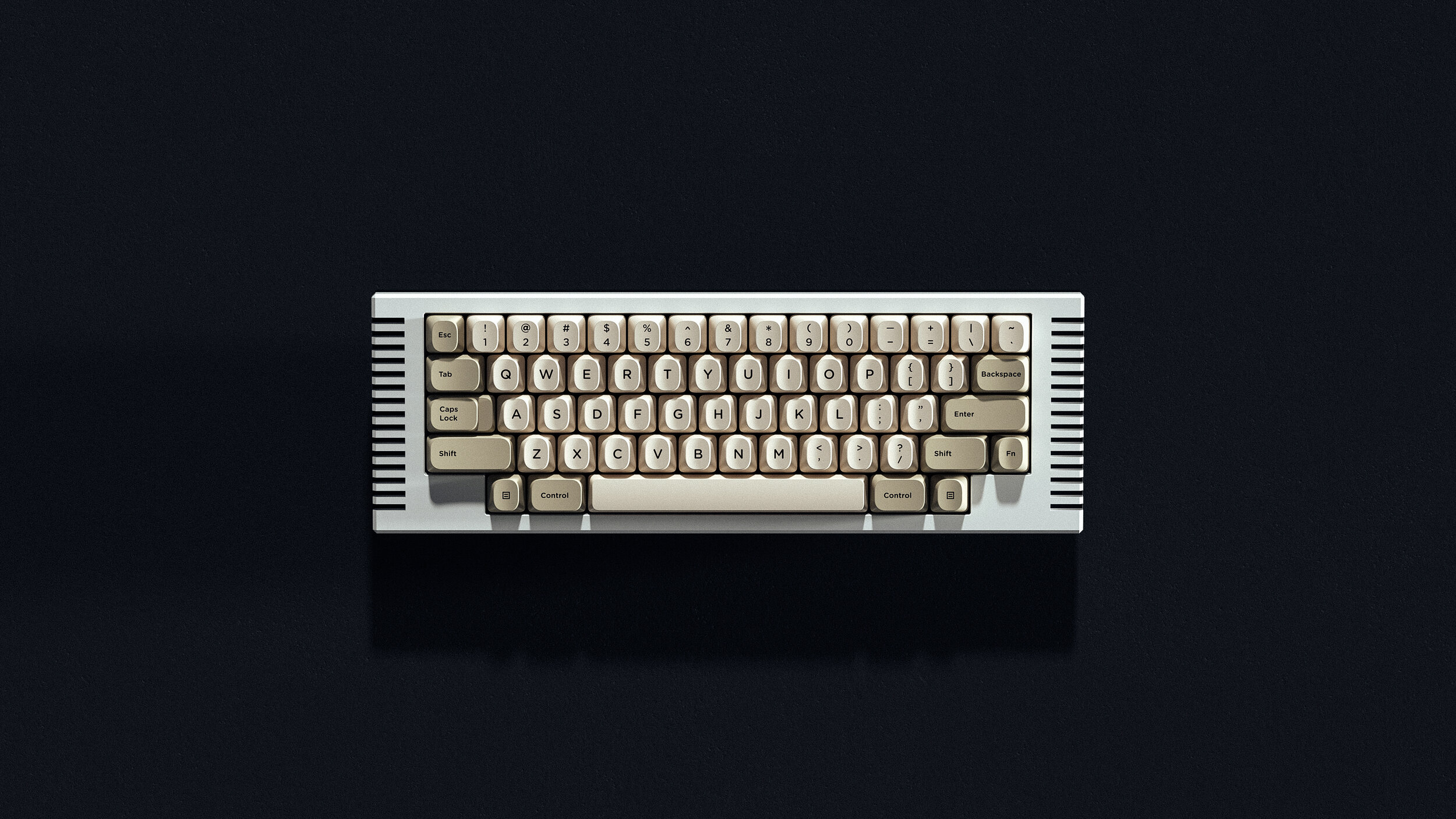

M60-B

STATUS: PRE-ORDER OPEN

The famed M60 silhouette returns with newly updated internals with the removal of the integrated plate in favour of the gasket mounted sub-assembly. Keeping its aesthetic beauty from its predecessor, first released in 2018, the M60-B has been re-engineered & designed to provide a modern typing experience with added compatibility with our KARA range. Pre-order closes on January 31st.

You can purchase the refreshed design with new innovative features using the link below:

https://ramaworks.store/products/m60-b

THERMAL SEQ2/THERMAL+

STATUS: IN PRODUCTION

PCB manufacturing will start in late February after the Chinese New Year festive period. Customer orders are expected to begin fulfilling in late Q2 2022. We will keep everyone updated as soon as we have more information on the PCBs completion and arrival at our warehouse.

CAPS/KATE KEYSETS

STATUS: PRE-ORDER CLOSED - PRE-PRODUCTION COMMENCED

We are finalising the legends and working on adjusting the casing tooling. Shipping will begin when manufacturing/assembly is complete.

M65-C

STATUS: PRE-ORDER CLOSED - PRE-PRODUCTION COMMENCED

The preorder period for M65-C is closed now, and production will commence shortly! Shipping will start when manufacturing/assembly is complete. Estimated fulfilment: Q4 2022

RAMA'S BURGERS T-SHIRT / INVENTORY 2 / KEYCAP

STATUS: FULFILMENT ABOUT TO COMMENCE

After receiving some inventory for the RAMA's Burger collection, we were hopeful the remaining would have arrived in December. Unfortunately, that was not the case due to a backlog in shipping and covid cases halting daily limits of shipments and delays, which were out of our control.

The good news….

We will have all the inventory shipped to us before Chinese New Year, so our warehouse will fulfil orders as soon as they arrive in Melbourne!

Please make sure your shipping address is correct! You can check by logging in at https://ramaworks.store/account/login and navigating to your order.

Note: Updating your default address will not update past orders.

If you need to update your shipping address, please get in touch with us at support@rama.works or https://support.rama.care/.

Remember to include your order number!

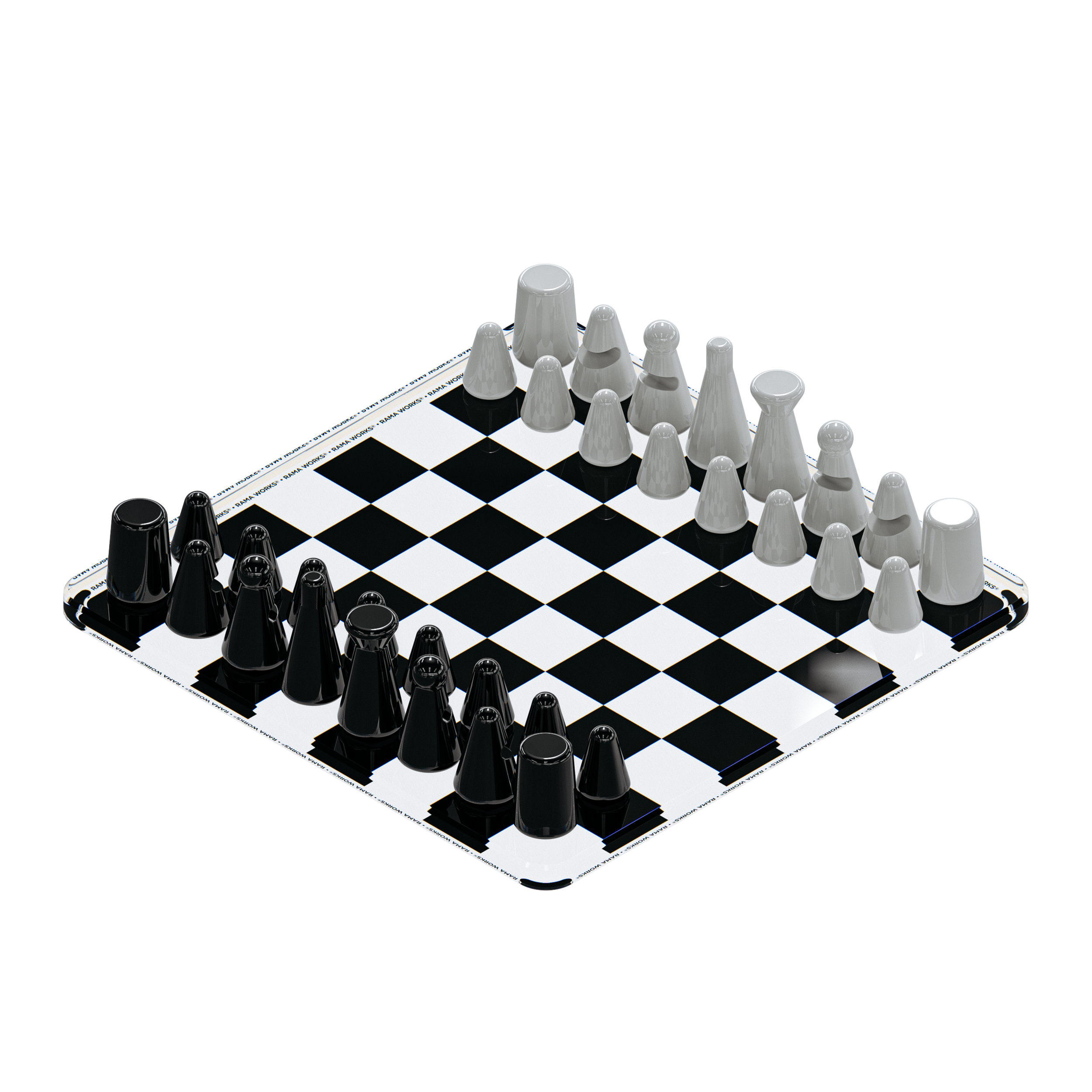

CHESS SET 01

STATUS: IN PRODUCTION

CHESS PIECES:

After careful consideration, we have opted to proceed with a more classical chess set look (white and black) with ceramic coating for durability and a superior finish. We have also installed silicone feet on the pieces to protect the board's surface and prevent slipping.

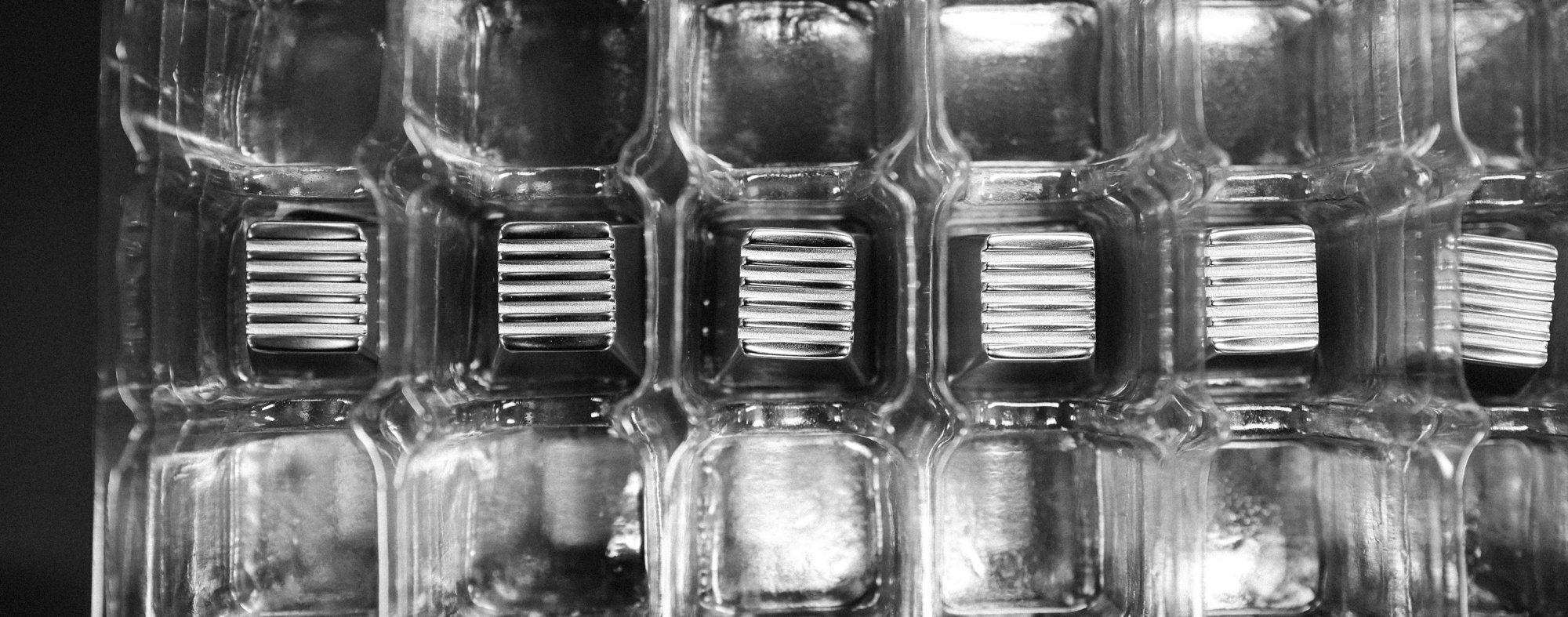

BOARD

The board features a thick 14mm acrylic base, with silkscreen graphics on the underside - encasing it below the crystal housing. The design of the board has remained essentially the same.

We always aim to provide the most pleasing end-user experience hence the change in finishing for the pieces. If you have any concerns or queries regarding your order, don't hesitate to get in touch with us at support@rama.works or: https://support.rama.care/.

XO PEN

STATUS: PRODUCTION NEARLY FINISHED

We will be receiving the XO PENS next month! Fulfilment of orders will begin when stock arrives at our Melbourne Distribution Center.

TRAY

STATUS: PRODUCTION COMPLETED - FULFILLMENT ABOUT TO COMMENCE

The TRAYS will be arriving this month so our warehouse can fulfil customer orders as soon as they arrive.

JARS

STATUS: PRE-PRODUCTION

The preorder period for the JARS has ended. Pre-production is currently underway.

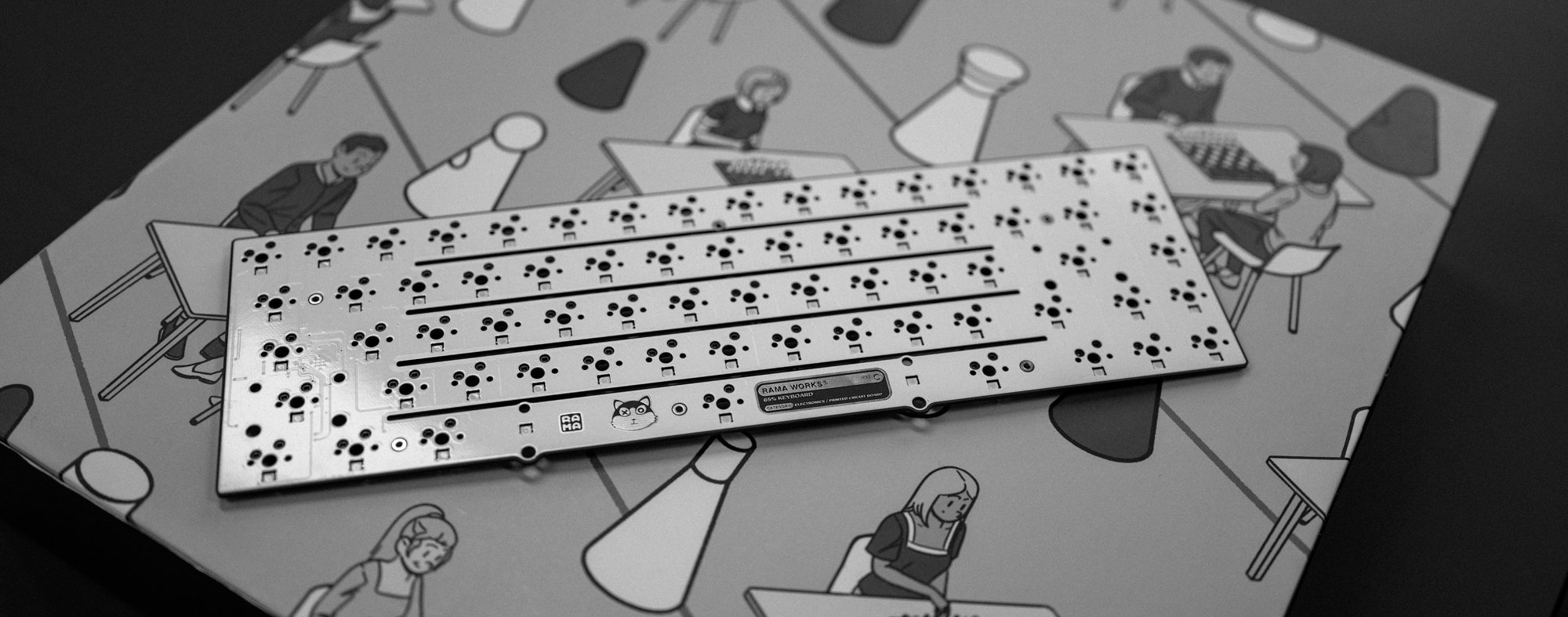

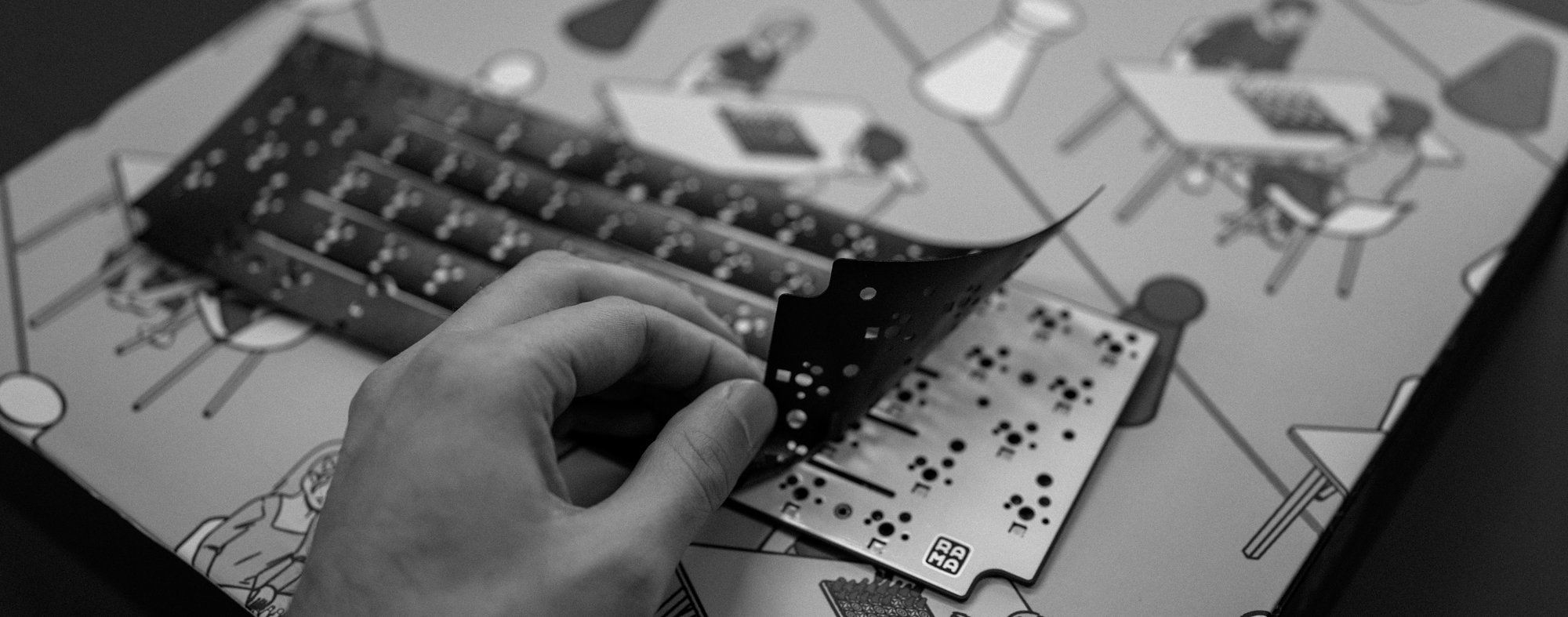

KARA SEQ2

STATUS: IN PRODUCTION

Production for the encasements is underway. We have changed the PCB design to add the flex cuts with the prototype arriving after Chinese New Year. Production on the new, improved design of the PCB can begin shortly after. We will keep everyone updated as soon as we have more information on when fulfilment can commence.

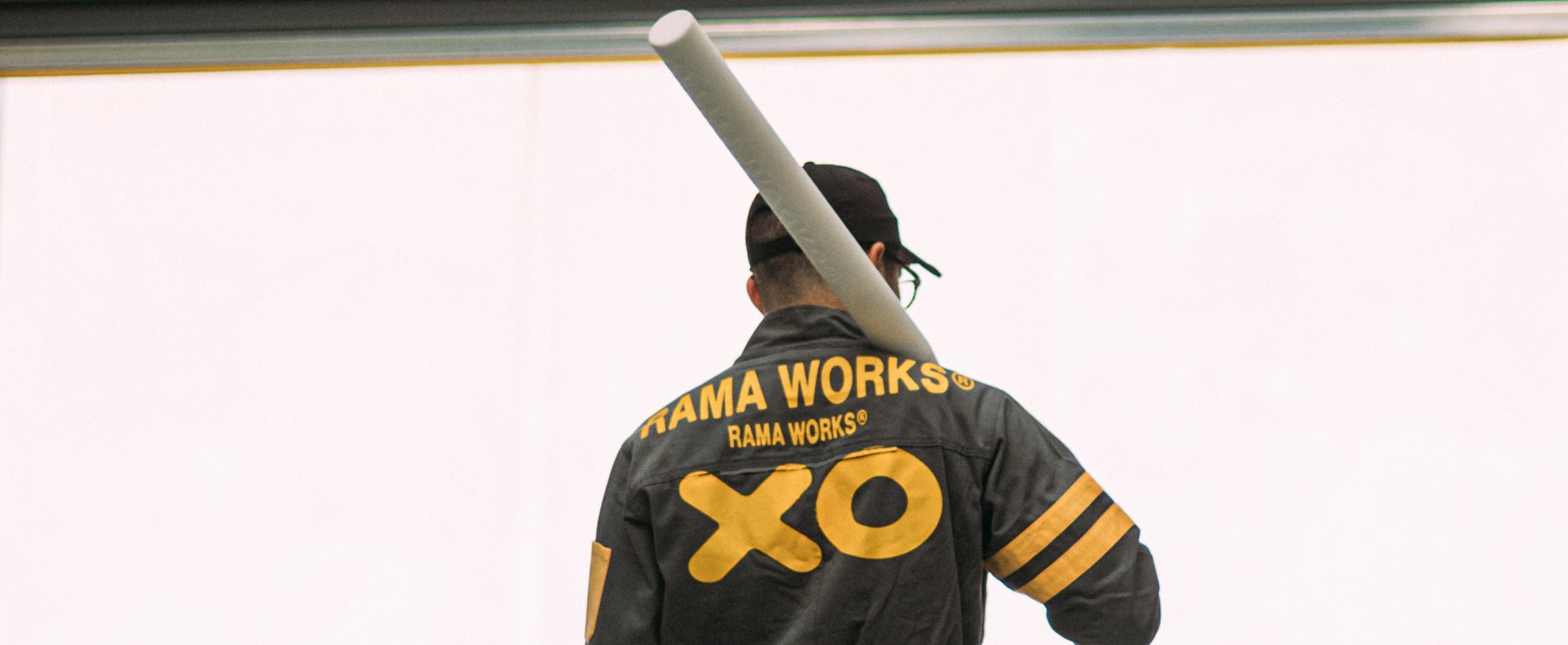

BAT

STATUS: Pre-Production

The latest off-tool samples have come out of the moulds with their final texture finish and are inbound to our HQ. We can't wait to show the pre-production samples when they land!