The team here at RAMA WORKS have been very dedicated to getting our orders and updates on track, doing what we love and producing top quality products. Thank you to all our loyal customers for being patient and for everyone’s support. Here are the following updates for our current projects. We have also been working away on some exciting new projects to come next year!

ZENITH

STATUS: FINISHED FULFILMENT

Our warehouse staff worked extremely hard to finish fulfilling all your orders. We hope all our customers are enjoying their brand new ZENITH. Make sure you share photos so we can see how yours have turned out! Tag @ramaworks on Instagram so we can reshare 🤗

If you have a support related inquiry, please contact us at support@rama.works or https://support.rama.care/

Remember to include your order number!

U80-A SEQ2

STATUS: FULFILMENT ABOUT TO COMMENCE

PCB:

The PCBs are finally on their way to our warehouse as we speak! Fulfilment can commence as soon as they arrive at our Melbourne distribution centre. The warehouse team has been very busy organising in preparation for the final components to arrive so we can get all your orders out the door as soon as they land.

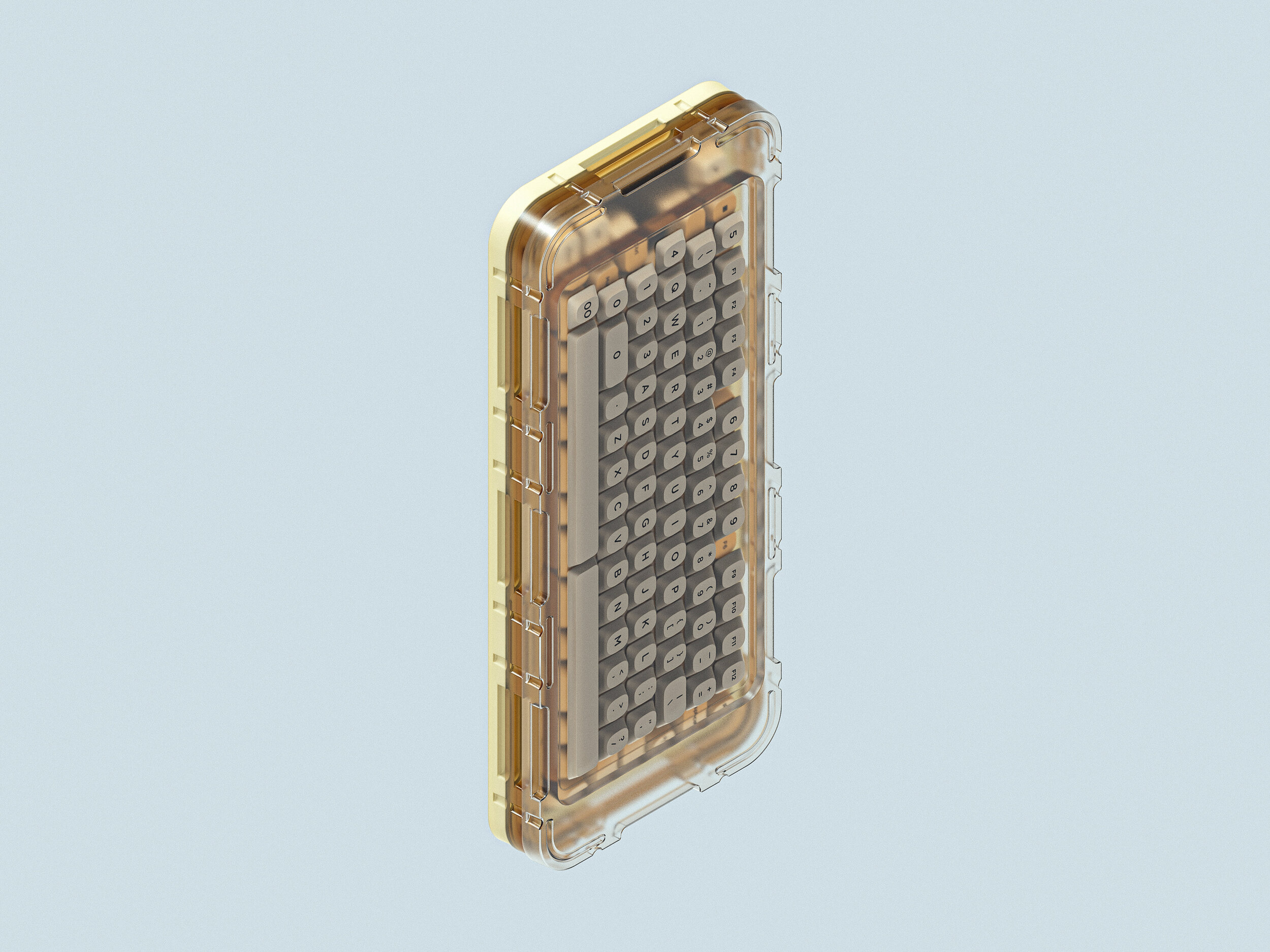

ENCASEMENT:

Encasements, U80 backplates, and internal weights are at our warehouse, awaiting the remaining PCB’s to begin the fulfilment of our orders.

We have been working around the clock to ensure that we can get these U-80-A SEQ 2 to all our customers after the long wait as soon as we receive all the necessary parts. We know this project has taken some time, and we thank you all for patiently waiting and being understanding of the current circumstances.

THERMAL SEQ2/THERMAL+

STATUS: IN PRODUCTION

Thermal SEQ2 and Thermal+ encasement are now complete after the desired rose-gold colour has been rectified. These should hopefully be shipped off soon to our warehouse and awaiting other components to fulfil our customer orders expected late Q1 2022. We will keep everyone updated as soon as we have more information.

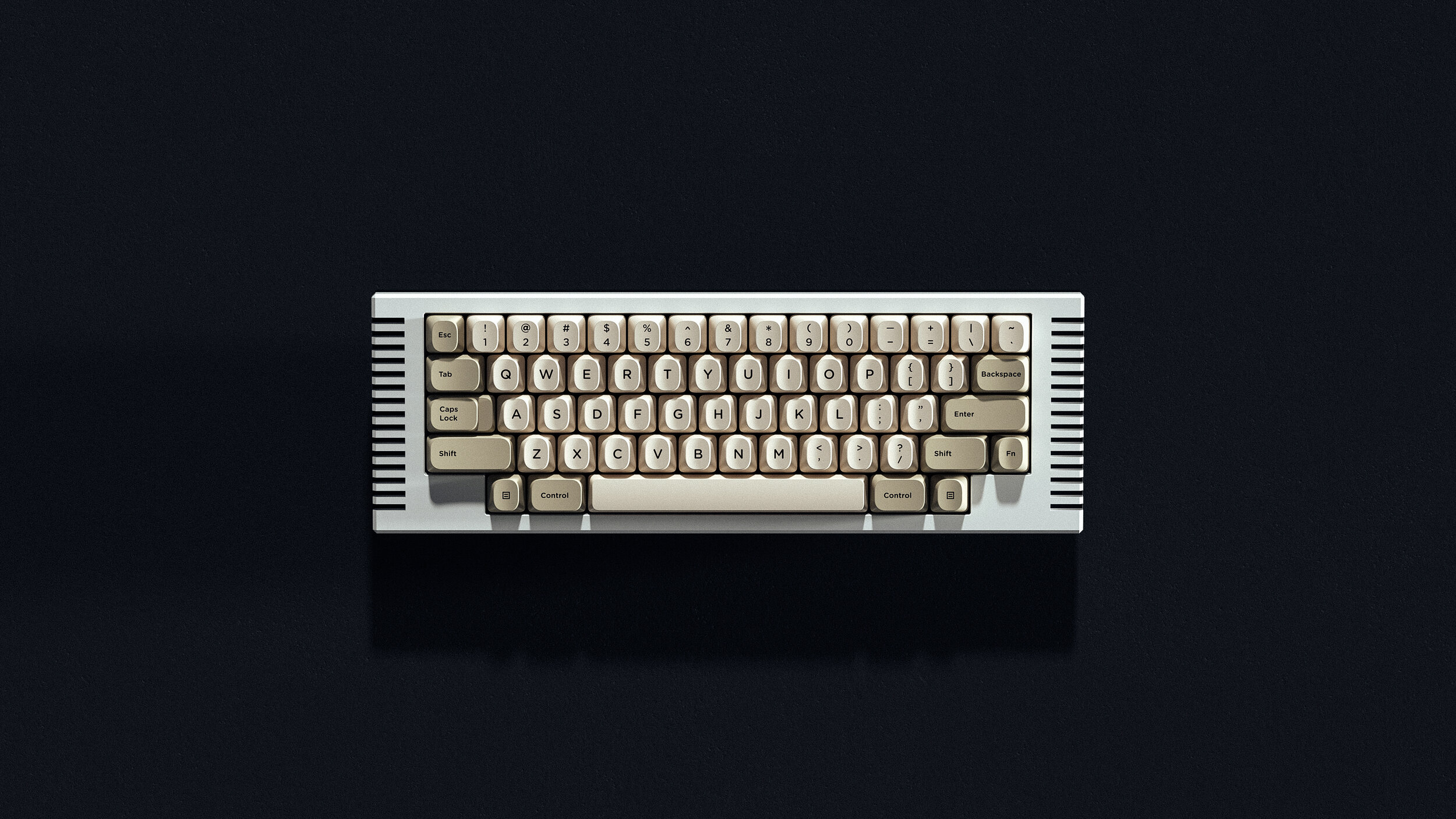

CAPS KEYSETS

STATUS: FINAL DAY TO PREORDER

By popular demand and with a bit of help from our manufacturing partners, we are proud to offer this product at a lower price point (excluding CASE). We have made some adjustments to the tooling (Currently at Off-Tool Samples 3 [T3]) and are now finalising the double-shot legends, but overall are very happy - production will be relatively quick when the tooling is complete. Rest assured, the CAPS will be of the high-quality standard and aesthetic of RAMA WORKS® and we are super excited to hear and see these on whichever board they crown!

See below photos of the latest tooled samples:

M65-C

STATUS: PRE-ORDER CLOSED - PRE-PRODUCTION COMMENCED

The preorder period for M65-C is closed now, and production will commence shortly! Shipping will start when manufacturing/assembly is complete. Estimated fulfilment: start of Q3 2022

RAMA’S BURGERS T-SHIRT / INVENTORY 2 / KEYCAP

STATUS: AWAITING TRANSIT

We have received some inventory for the RAMA’S Burgers collection. We are waiting for the rest of the inventory to arrive before fulfilment to our customers will commence. We will update everyone as soon as the rest of the products land.

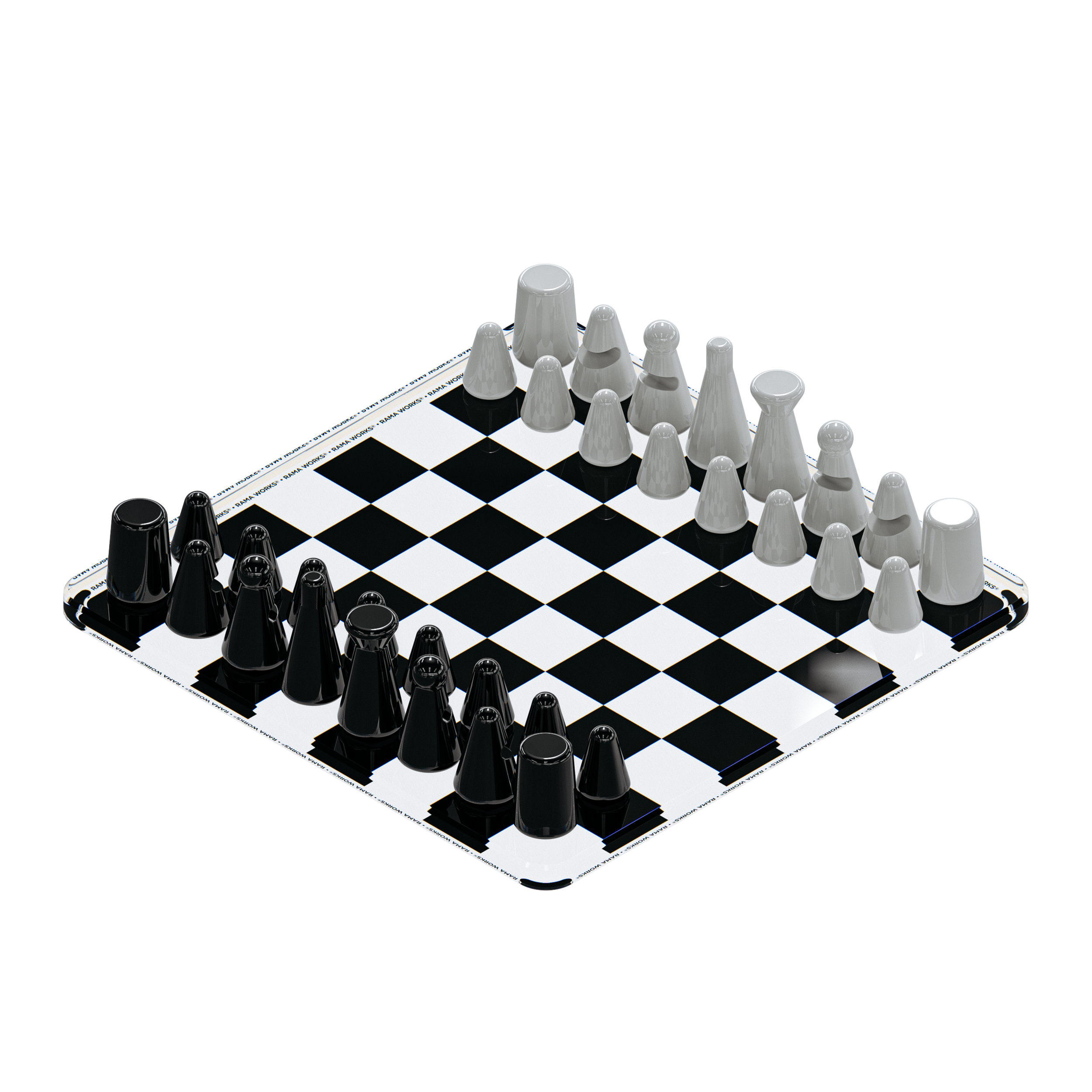

CHESS SET 01

STATUS: IN PRODUCTION

CHESS PIECES:

After careful consideration, we have opted to proceed with a more classical chess set look (white and black) with ceramic coating for durability and a superior finish. We have also installed silicone feet on the pieces to protect the board’s surface and prevent slipping.

BOARD

The board features a thick 14mm acrylic base, with silkscreen graphics on the underside - encasing it below the crystal housing. The design of the board has remained essentially the same.

We always aim to provide the most pleasing end-user experience hence the change in finishing for the pieces. If you have any concerns or queries regarding your order, please contact us at support@rama.works or https://support.rama.care/

XO PEN

STATUS: IN PRODUCTION

The ink refill for the XO PEN is currently being sourced.

TRAY

STATUS: IN PRODUCTION

Production will be completed by the end of the month. Fulfilment of orders will begin when the TRAY arrive at our Melbourne distribution centre.

JARS

STATUS: PRE-PRODUCTION

The preorder period for the JARS has ended. Pre-production is currently underway.

KARA SEQ2

STATUS: IN PRODUCTION

RAMA WORKS® x @st_ali 🇮🇹💚☕️🤍☕️❤️🇦🇺

Status: WIP